Concrete is everywhere in New Zealand—homes, shops, warehouses, and even outdoor patios. But over time, concrete floors can become rough, stained, cracked, or just plain dull. That’s where concrete grinding comes in. This process can turn tired, uneven concrete into a remarkable, modern surface that’s both beautiful and practical.

Whether you’re renovating a classic Kiwi villa, upgrading a commercial space, or just want a low-maintenance floor for your garage, concrete grinding and polishing offer a cost-effective way to revive your floors. Let’s explore how this process works, what it can do for your property, and why more New Zealanders are choosing polished concrete floors.

Concrete grinding is the process of using heavy-duty machines fitted with diamond abrasives to remove the top layer of a concrete slab. This can eliminate surface imperfections, old coatings, glue, paint, and even high spots. The result? A smooth, level, and clean surface ready for polishing, sealing, or resurfacing.

Every floor is different, but most floor grinding services in New Zealand follow a similar multi-stage process:

| Feature/Option | Raw Concrete | Grind & Seal | Polished Concrete |

|---|---|---|---|

| Surface Smoothness | Rough | Smooth | Mirror-like |

| Maintenance | High | Low | Very Low |

| Stain Resistance | Poor | Good | Excellent |

| Slip Resistance | Variable | Good | Customisable |

| Aesthetic Appeal | Basic | Modern | Premium |

| Lifespan | 10–15 years | 15–20 years | 20+ years |

| Typical Use | Garages, Basements | Retail, Warehouses | Homes, Offices, Showrooms |

| Cost (per m², NZD)* | $30–50 | $60–90 | $90–150 |

*Estimates only. Actual costs depend on floor size, condition, and finish.

New Zealand’s climate can be tough on floors—think muddy boots, sand, and wet weather. Polished concrete floors are:

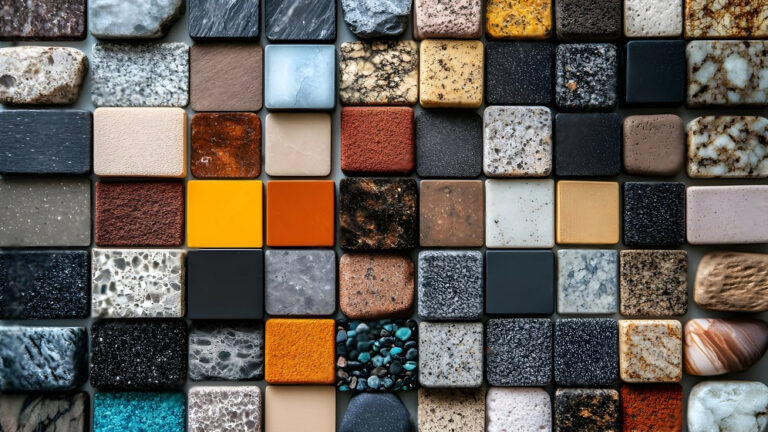

When it comes to concrete floor finishes, homeowners and businesses have a wide range of options to match their style and functional needs. Here are some of the most popular finishes you’ll find across New Zealand:

This finish reveals the natural stones and pebbles within the concrete, creating a textured, decorative look. Exposed aggregate is a favourite for driveways, patios, and pool surrounds because it’s durable, slip-resistant, and visually striking.

Honed concrete floors are achieved by grinding the surface to a smooth, matte finish without reaching a high gloss. This style is popular for both indoor and outdoor spaces, offering a modern, understated look that’s easy to maintain.

This finish lightly grinds the surface to expose fine sand and small aggregate particles, giving a subtle, speckled appearance. It’s a great choice for those wanting a contemporary look with a bit of texture.

Burnished concrete is created by polishing the surface with a steel trowel or burnishing machine, resulting in a smooth, slightly reflective finish. It’s often used in commercial spaces for its clean, industrial vibe.

For those seeking a show-stopping floor, a high-gloss mirror polish delivers maximum reflectivity and a sleek, modern feel. This finish is ideal for showrooms, retail spaces, and high-end homes where visual impact is key.

Modern designer concrete floors offer a surprising range of customisation. Here’s how you can tailor your polished concrete to suit your space:

Concrete can be coloured with stains or dyes to achieve anything from natural earth tones to bold, contemporary hues. This allows for unique concrete floor colours that match your décor.

You can choose how much of the stone and sand within the concrete is exposed—ranging from a light “salt and pepper” look to full aggregate exposure for a more dramatic effect.

Decorative saw cuts or scoring can create patterns, borders, or even replicate the look of large tiles. This adds visual interest and can help define different areas within open-plan spaces.

For commercial clients, inlays or custom logos can be embedded into the floor, making a strong brand statement in lobbies, showrooms, or retail spaces.

With these options, polished concrete is as much about design as it is about durability.

Choosing the right flooring is a big decision for any Kiwi home or business. Here’s how polished concrete vs tiles and other common flooring options stack up in terms of durability, maintenance, and lifespan:

| Feature | Polished Concrete | Vinyl | Laminate | Tiles | Timber |

|---|---|---|---|---|---|

| Durability | Excellent | Moderate | Moderate | High | Moderate |

| Maintenance | Low | Low | Moderate | Moderate | High |

| Lifespan | 20+ years | 10–15 years | 10–15 years | 20+ years | 10–20 years |

| Water Resistance | High | High | Low–Moderate | High | Low |

| Scratch Resistance | High | Moderate | Low | High | Low–Moderate |

| Allergen Friendly | Yes | Yes | Yes | Yes | No |

| Eco-Friendly | Yes | Sometimes | Sometimes | Sometimes | Sometimes |

| Style Options | Customisable | Many | Many | Many | Limited |

| Best For | Homes, offices, retail, garages | Kitchens, bathrooms | Bedrooms, living areas | Bathrooms, kitchens, outdoors | Living areas, bedrooms |

Polished concrete stands out for its long-term value, low upkeep, and modern look, making it one of the best flooring for NZ homes and businesses.

Concrete grinding isn’t just for interiors. Outdoor applications are growing in popularity across the country, especially for:

Benefits of grinding and polishing outdoor concrete include:

Grind outdoor concrete for a surface that’s both practical and visually appealing.

While you can hire a local grinder for concrete floors, professional concrete grinding services offer:

DIY is possible for small, simple jobs, but for best results—especially for polished concrete installation—it’s worth hiring experienced concrete polishing contractors.

To keep your polished concrete looking its best, follow these simple polished concrete maintenance tips:

With the right care, your polished concrete floor will stay beautiful and functional for decades. For more concrete floor care tips, ask your installer for a tailored maintenance plan.

Concrete grinding and polishing have changed the way Kiwis approach flooring—indoors and out. Whether you want to revive an old garage, create a stunning kitchen, or upgrade your business or outdoor space, concrete grinding and polished concrete floors deliver a blend of style, strength, and sustainability that’s hard to beat.

With a wide range of finishes, colours, and design options, you can achieve a look that’s uniquely yours—while enjoying a floor that’s easy to clean, tough enough for New Zealand’s climate, and built to last. From exposed aggregate patios to high-gloss showroom floors, the possibilities are nearly endless.

Ready to see the difference for yourself? At Polished Concrete Floors, we’re New Zealand’s trusted experts in concrete floor polishing, grinding, and restoration. Our skilled team delivers premium results for homes, offices, warehouses, and more—across Auckland and major cities nationwide.

Contact us today for a free quote or to discuss your project. Let’s turn your rough concrete into something truly remarkable.

The cost to grind and polish concrete in New Zealand varies depending on several factors, including the size of the area, the condition of the existing floor, and the desired finish. On average, you can expect to pay between 60 and 150 per square metre for a full grind and polish, with basic grind and seal options being more affordable and high-gloss finishes at the higher end. Additional costs may apply for surface preparation, repairs, or if a densifier is required to strengthen the concrete before polishing.

Choosing this method is often more cost-effective in the long run compared to installing new flooring materials, as polished concrete is durable and requires minimal maintenance. For those seeking an affordable yet stylish flooring solution, concrete grinding and polishing offer a fast transformation that enhances both residential and commercial spaces. Always request a detailed quote from your contractor to ensure all aspects of the job are covered.

Concrete grinding is a process that uses heavy machines equipped with diamond-embedded discs to remove the top layer of a concrete surface. This method eliminates imperfections, old coatings, and high spots, resulting in a smooth, level base ready for further enhancement such as sealing or polishing. The process can also prepare the surface for new flooring installations, making it a versatile solution for many property types.

Concrete grinding is the right solution when you need to address issues like cracks, stains, or uneven surfaces, or when you want to upgrade the look of your floors without a full replacement. It’s especially beneficial in high-traffic areas like entryways, warehouses, and retail spaces where durability and appearance are important. If you’re looking for a dustproof, low-maintenance, and modern flooring option, concrete grinding is a smart choice.

Yes, you can polish already poured or existing concrete floors, even if they have lost their original shine over time. A professional polisher can restore the surface by using a series of increasingly fine abrasives to remove surface wear and bring back a deep, reflective finish. This process not only revives the appearance of the floor but also improves its durability and resistance to stains.

Polishing existing concrete is a sustainable and eco-conscious way to enhance your space, as it avoids the need for new materials and reduces waste. Whether your floor is in a home, office, or commercial setting, this enhancement can breathe new life into tired concrete, making it look modern and fresh again. Regular maintenance and occasional re-polishing will keep your floor looking its best for years to come.

Grinding concrete can be physically demanding and potentially hazardous, especially without the right equipment and safety precautions. The process involves abrasion with heavy, industrial-grade machines that generate significant dust and noise. Proper ventilation and dust extraction are essential to maintain good air quality and protect your health during the job. Additionally, handling powerful tools like a handheld grinder or a large floor grinder requires experience to avoid injury or damage to the floor.

While it is possible to rent equipment and attempt small projects at home, most experts recommend hiring professionals for anything beyond minor touch-ups. Professionals have the skills, safety gear, and knowledge to achieve a high-quality finish efficiently and safely. Attempting DIY concrete grinding without proper training can lead to uneven results, excessive dust, and even personal injury.

Fixing uneven or settling concrete typically starts with a thorough assessment to determine the cause and extent of the problem. For minor issues, a polisher may use a heavy-duty grinder with a specialized disc to level the surface and create a smooth, even finish. This approach is especially effective for entryways, patios, and walkways where a level surface is important for safety and appearance.

In cases of significant settling or deep cracks, more extensive repairs may be needed, such as slab jacking or replacing sections of concrete. Addressing these issues promptly not only improves the look of your property but also prevents further damage and potential hazards. A professional can recommend the best solution for your specific situation, ensuring a long-lasting and dustproof result that enhances your property’s value and usability.